The “masterbatch” came about long before thermoplastics existed: Natural rubber mixed with sulphur, zinc oxide and chalk. Starting around 1910, carbon black is used to make tyres abrasion-resistant. And also black.

The pan grinder is used to finely grind and mix colour pigments. These powder mixtures are used to produce compounds or to colour directly on the processing machine. Both mass products and design icons are created.

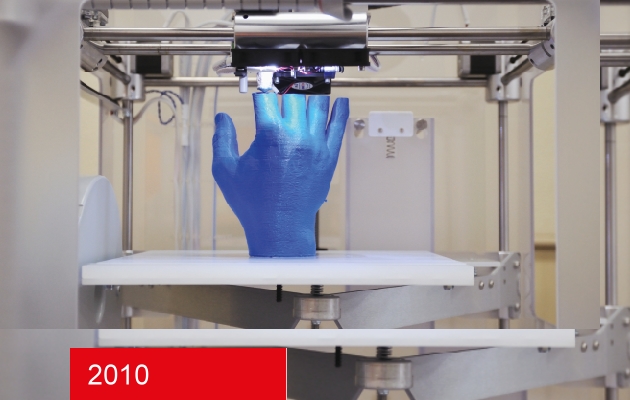

Colour and additive masterbatches provide an ever-increasing variety of plastic products. Small amounts of the concentrates enable individualization, for example, using 3D printing. At this point, Masterbatchers supply colours to the manufacturers of printing filaments or they even produce the filaments themselves. The fast and flexible support and transport of the material developments are vital to 3D printing. Masterbatchers are important partners in this innovative industry because product development always concerns small quantities.

and now

Plastics are both raw materials and reusable materials. “Medical grade plastics” improve the lives of many. They allow facades to store heat. They enable lightweight construction – and they are, therefore, an integral part of mobility of the future.